Whether you want to import or learn more about sintered metal fiber felt, all information you are looking for is right here.

Keep reading if you want to be an expert in sintered metal fiber felt.

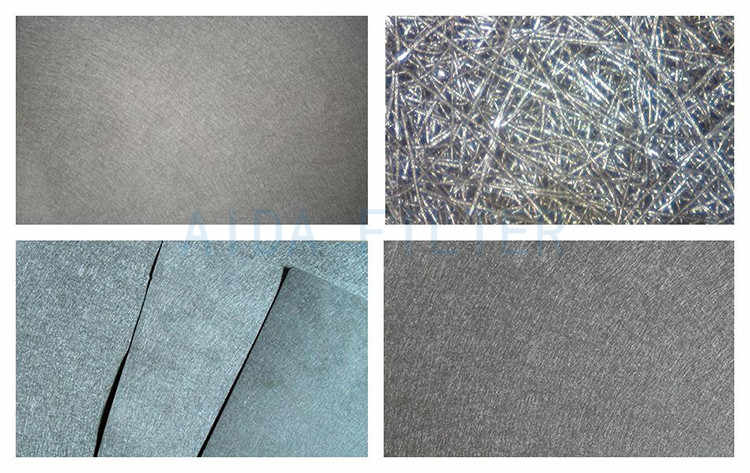

What is Sintered Metal Fiber Felt?

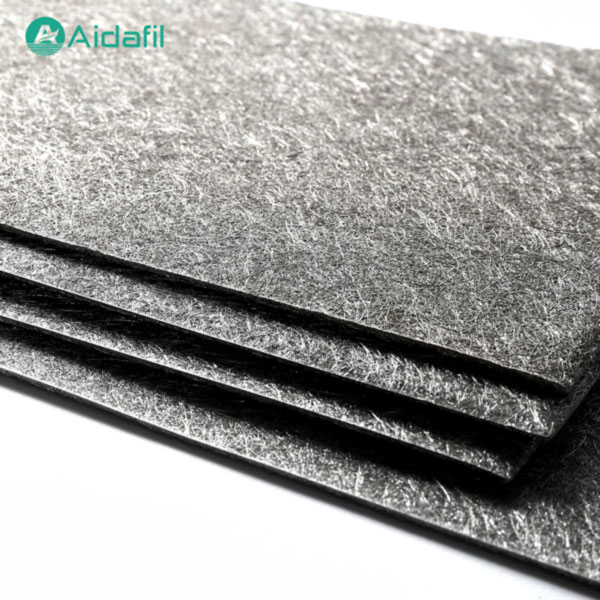

It is made of extremely fine stainless steel metal fiber (accurate to micron in diameter) which is made by non-woven layering and superimposed by high temperature sintering.

Sintered metal fiber felt is best suited for use in applications that operate under very high pressure, high temperature, and corrosive environments.

The stainless steel sintered felt is formed by different orifice gradients, which can be controlled to obtain high filtering precision and greater amount of contamination

The fleece of the metal fiber can comprise different layers of fiber.

They can be compressed together to a suitable thickness then sintered to fuse the respective single fibers..

What is the function of Sintered Metal Fiber Felt?

A sintered metal fiber felt is a porous material that offers superior filtration capabilities over other types of filtration media.

It has excellent filtration properties, which makes it a good choice for constructing a filtration element.

Consequently, you can add the material as a single layer on a sintered filter element or sintered mesh.

You can also sinter together multiple layers of the materials to construct a complete filter media.

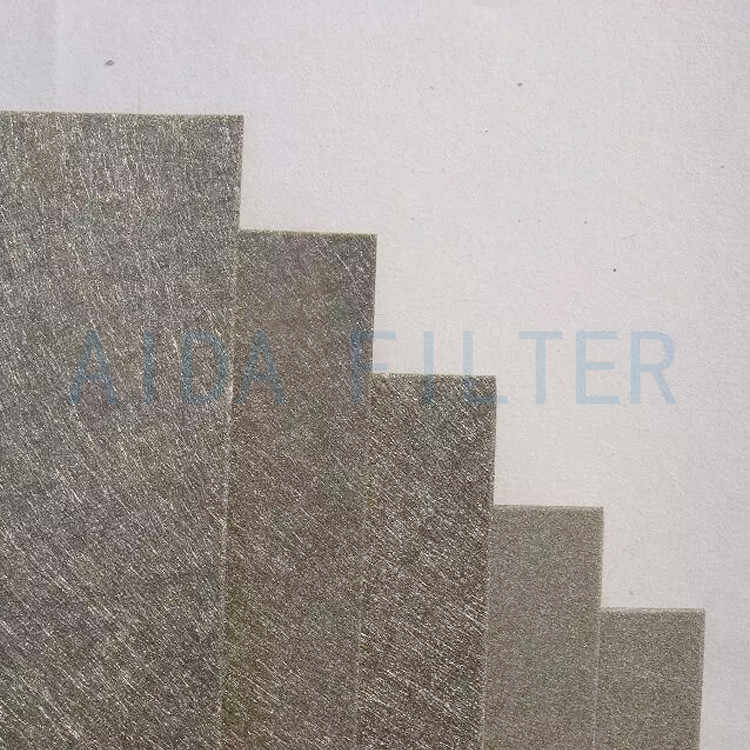

What is the specifications of Sintered Metal Fiber Felt?

● Item: stainless steel sintered fiber felt.

● Standard Materials: 316L stainless steel fiber.

● Filter rating: 99%.

● Standard Length: 1200mm.

● Standard Width: 1000mm.

● Thickness: 0.3–0.68 mm.

● Porosity: 75% – 85%.

standard size : 1000x500 1000x600 1000x1000 1200x1000

The dimensions in the above range can be customized according to user requirements.

product specification |

Filter Precision (μm) |

Bubbling point pressure (pa) |

Air permeabilityL/(min,dm2,kpa) |

porosity(%) |

containment capacity(mg/c㎡) |

Thickness(mm) |

fracture strength(Mpa) |

Mark |

basic value |

basic value |

basic value |

basic value |

basic value |

basic value |

|||

ADZB-5 |

5 |

6800 |

47 |

75 |

5 |

0.3 |

32 |

|

ADZB-7 |

7 |

5200 |

63 |

76 |

6.5 |

0.3 |

36 |

|

ADZB-10 |

10 |

3700 |

105 |

75 |

7.8 |

0.37 |

32 |

|

ADZB-15 |

15 |

2450 |

205 |

79 |

8.6 |

0.4 |

23 |

|

ADZB-20 |

20 |

1900 |

280 |

80 |

15.5 |

0.48 |

23 |

|

ADZB-25 |

25 |

1550 |

355 |

80 |

19 |

0.62 |

20 |

|

ADZB-30 |

30 |

1200 |

520 |

80 |

26 |

0.63 |

23 |

|

ADZB-40 |

40 |

950 |

670 |

78 |

29 |

0.68 |

26 |

|

ADZB-60 |

60 |

630 |

1300 |

85 |

36 |

0.62 |

28 |

|

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

Deviation of 10% |

NOTE:

1. The determination of filtration precision and contamination capacity shall be conducted in accordance with GB/T 18853-2002.

2. The measurement of bubble point pressure shall be conducted in accordance with GB/T5249.

3. The measurement of air permeability is conducted in accordance with GB/T5453 and the pressure difference is 200Pa and the medium is air.

4. The determination of fracture strength shall be conducted in accordance with GB/T228.

How is Sintered Metal Fiber Felt Manufactured?

1. Heat the sintered metal fiber felt in a vacuum sintering furnace to between 300 ℃ and 600 ℃. Keep these temperatures for 30 to 120 minutes.

2. Carry out low temperature sintering. You will obtain a low temperature sintered metal fiber felt after natural cooling.

3. The low-temperature sintered felt is compressed by a hydraulic press to achieve a porosity of 60-90%.

4. The compressed sintered metal fiber felt is returned to the vacuum furnace and heated to 900C to 1000 °C. Keep the temperature for 1 to 30 minutes.

5. Carry out high temperature sintering. Let it cool naturally to obtain high quality sintered metal fiber felt.

What are the features and benefits of a Sintered Metal Fiber Felt?

● High temperature and corrosion resistance. Can be used in 480 ℃ environment medium for a long time.

● Easy to process, shape and weld.

● High dirt holding capacity.

● High porosity and excellent permeability.

● High stain resistance capacity.

● Long replacement cycle;

● Little pressure loss and large flow.

● Can be welded and machined because of its large filter area.

● Easy to clean and can be used for a longer time.

● Can produce reinforced, thickened, protected and other specifications according to user's requirement.

What Applications use Sintered Metal Fiber Felt?

You can use sintered metal fiber felt in numerous applications requiring fine, deep, and sub-micron filtration such as:

● Polymer filtration and polyester melt purification.

● Filtration of refining process, pre-filtration of ultrafilter.

● Electronic high temperature gas dust removal.

● Liquid purification in pharmaceutical, petroleum, biology and beverage industries.

● Vacuum pump protection filter, filter membrane support, catalyst carrier.

● Radiation of materials for manufacturing burners

● Airbags of cars and fuel filtration of aircraft and ships.

● Ventilations in nuclear applications

● Hydraulic system filtration.