Aida Nickel Foam Description

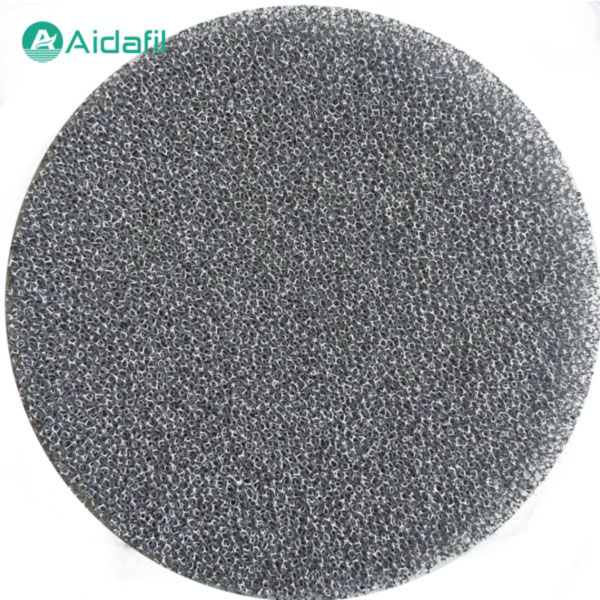

Nickel foam has good strength, toughness and corrosion resistance, and can be made into continuous roll nickel foam and sheet nickel foam according to practical applications, and different thicknesses are available. The products are mainly used as nickel-metal hydride rechargeable batteries, lithium batteries, fuel cells, air energy batteries, positive plate materials for solar cells, special filter materials, catalyst carriers, heat dissipation materials, damping materials, sound-absorbing materials, etc.

Aida Nickel Foam Technical parameter

Aperture |

0.1-10mm |

PPi (holes per inch of length) |

5-130PPi |

Bulk density |

≥0.1g/cm |

Through hole rate |

≥98% |

Thickness |

5-80mm |

Compressive strength |

≥250KPa |

Heat transfer coefficient |

≥3w(㎡K) |

High temperature resistance |

980°C |

Mechanical strength |

≥2-7MPa |

Tensile strength |

≥8-50MPa |

Maximum Geometry |

Cut to Request |

Aida Nickel Foam Features

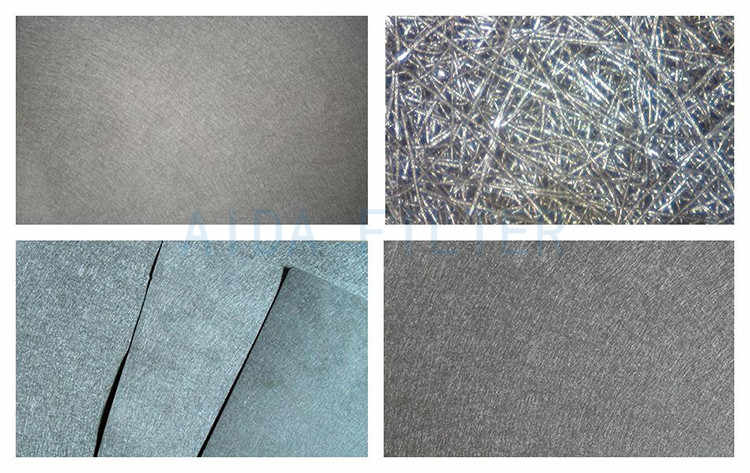

Porous nickel foam is a metal material with a certain amount, a certain size of pore size, and a certain porosity of a porous structure in the metal collective. Features are as follows:

High porosity: Almost fully transparent structure with a porosity of more than 98%, as a filter material, the pressure drop is small and the flow rate is high

Large surface area: Compared with other porous materials, it has the largest specific surface area under the same porosity

Sound Absorption: The porous structure has a wide frequency sound absorption characteristic

High processing performance: It can be lowered, bent, and easily adhered

Recycling: Metal waste can be recycled 100%

Insulation: With additional processing, high noise shielding can be obtained, and the sound insulation effect is good

High temperature resistance, resistance to various acid corrosion

Production principle

The production principle is to electroplate the required foam metal on the special polymer material skeleton with a three-dimensional network structure, such as polyurethane, polyester urethane and other special polymer materials. The polymer material and the reduced metal oxide are processed by chemical heat treatment to form a metal foam product.

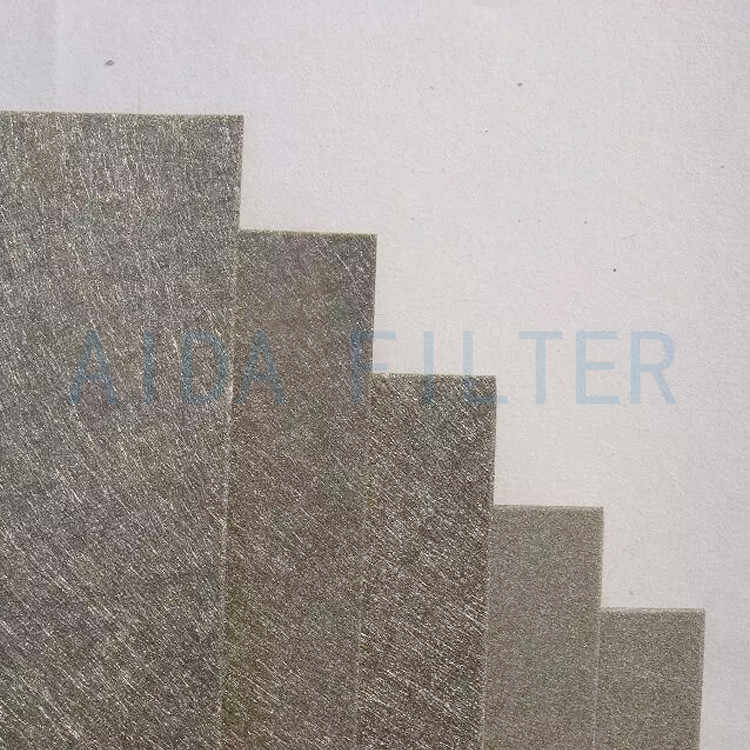

Performance Index

Project |

Performance index of continuous nickel foam |

Performance index of super thick nickel foam |

Thickness |

(1.0-2.5)±0.05mm |

(2.6-12)±0.05mm |

PPI |

60-130 |

60-130 |

Area density |

(300-500)±30g/㎡ |

(400-2000)±30g/㎡ |

Compressive strength |

portrait≥130N/cm²,transverse≥100N/cm² |

|

Elongation |

portrait≥5%,transverse≥12% |

|

Porosity |

≥96% |

≥96% |

Width |

(50-960)±0.5mm |

(50-960)±0.5mm |

Binding times |

200m≤4 contacts |

Maximum length 1000mm |

Specific resistance |

≤5x10^-6 |

≤5x10^-6 |

Aida Nickel Foam Applications

Filter material

Because of its excellent permeability, foam metals are widely used in the filtration industry, especially in industrial filtration, and can be made into many kinds of filters. The principle is that the pores of foam metal materials have the function of stopping and trapping solid particles contained in the fluid, filtering and separating gas or liquid, and then purifying or separating the medium. Foam metal filters can filter solid particles and other substances from liquid (such as petroleum, gasoline, refrigerant, polymer melt and suspension, etc.), or air and other airflow media. Commonly, the properties of filter elements are tubular, plate-like, flaky, plate-shaped and cup-shaped.

Photocatalyst series air filter screen

The photocatalyst materials used in this series of air filter screen are Nano fine compound composite powder manufactured by high technology and evenly deposited on the carrier surface by power coating or electrostatic spraying. There are paper-based photocatalyst filter screen, honeycomb photocatalyst filter screen, fibrous photocatalyst filter screen, gold photocatalyst filter screen and other types, Combined with ultraviolet light irradiation, it can quickly decompose the smoke, impurities and peculiar smell in the air, so as to achieve the effect of cleaning and filtration.

Chemical catalyst and support materials

Foam metal has the characteristics of porous and large surface area, and is different from the commonly used non-metal and oxide catalysts and catalyst carriers. It has high ductility, high thermal conductivity, especially good mechanical properties, and is easy to be processed into various shapes. The application range is ten wide, and the porous foam metal has many openings. It shows good hydrodynamic properties. Therefore, it has very significant advantages in the catalytic reaction of gas and liquid. In catalytic reaction, foam metal can be directly used as catalyst or foam metal as a carrier.

Battery electrode material

The foam metal has the electrical conductivity and self supporting ability of the serial number. There are a large number of pores in it, which can provide a large specific surface area. It is an excellent electrode material. It is suitable for various batteries, fuel cells, air batteries and solar cells, as well as various electrochemical process electrodes.

Heat exchange and adsorption materials

The foam metal has three-dimensional three-dimensional porous structure, large specific surface area and good thermal conductivity of the metal itself. When gas or liquid flows through the pores of the foam metal, it will take away heat or increase heat, so that the foam metal will be cooled or heated to achieve heat exchange. It is an effective material for heating, heat dissipation and heat exchange.