Polypropylene filter cloth plate and frame filter press industrial filter cloth

Precision:1-100μm

Filter cloth is a filter medium accumulated by fibers or synthetic fibers. Synthetic fibers mainly include polypropylene, cotton, polyester, vinylon, etc., of which polyester and polypropylene are most commonly used,mainly for solid-liquid separation, while cotton fiber is widely used in coal washing plants because ofits excellent wear resistance.

Filter cloth is mainly used for air filtration, dust cleaning and dust collection. It is widely used in smelting plants, chemical plants, sugar making, dyes, food and other industries.

filter cloth for Filmac SO 3-800-51.25.16 frame filter press used for filtration of uranium–containing pulp (uranium peroxide crystals), the technical characteristics of which are indicated in the table: EN TRU code 139616.900.000002

Specifications:

Density - 910 kg/m3

Melting point - 180 °C

Viscosity temperature - 140 °C

Number of threads (base) - 7744-7946

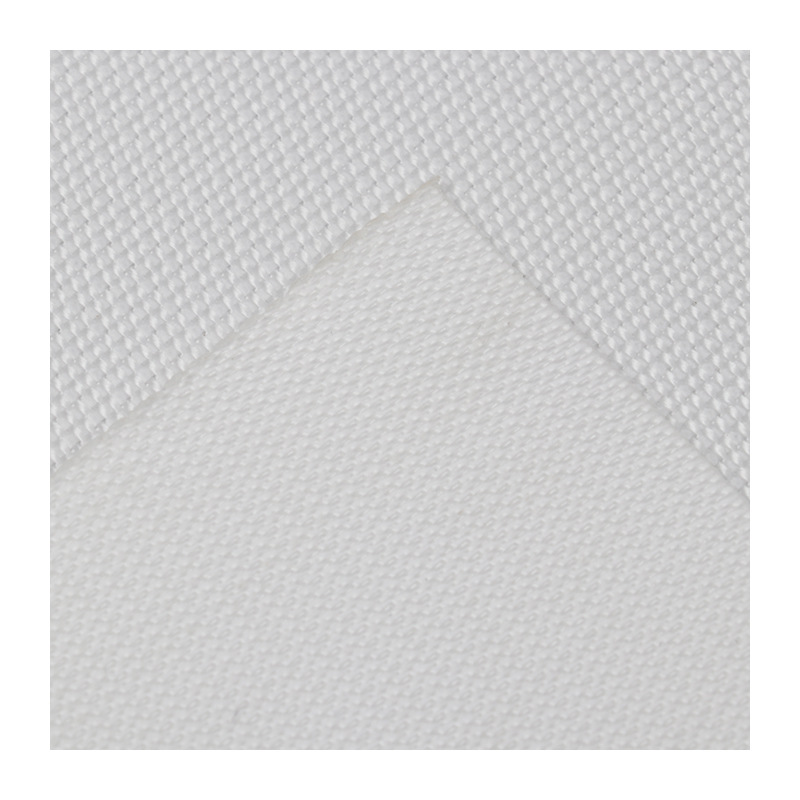

Number of threads (weft) - 3845-3975

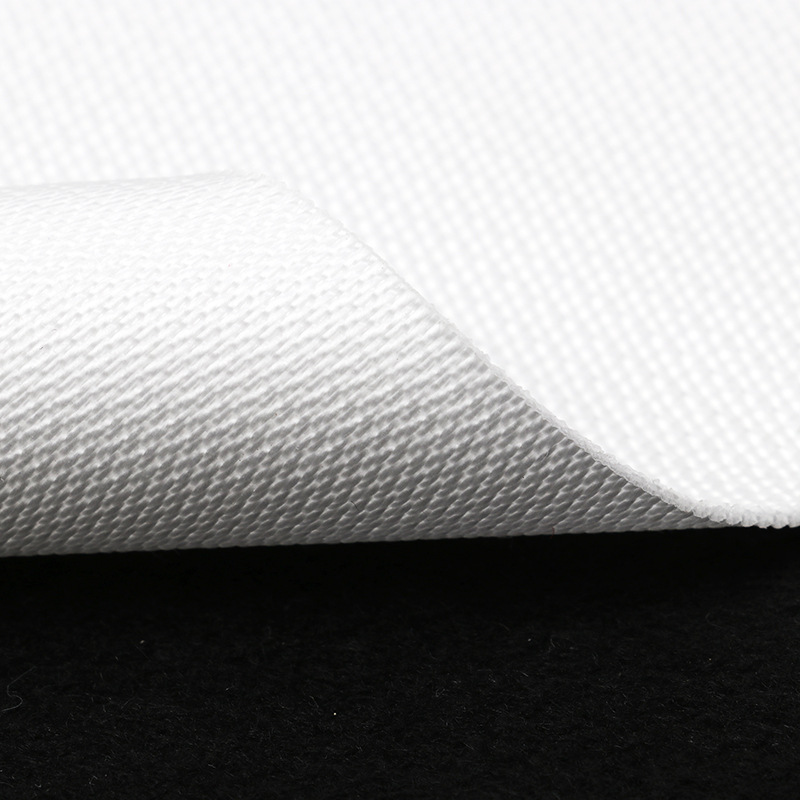

Thickness - 0.8 mm

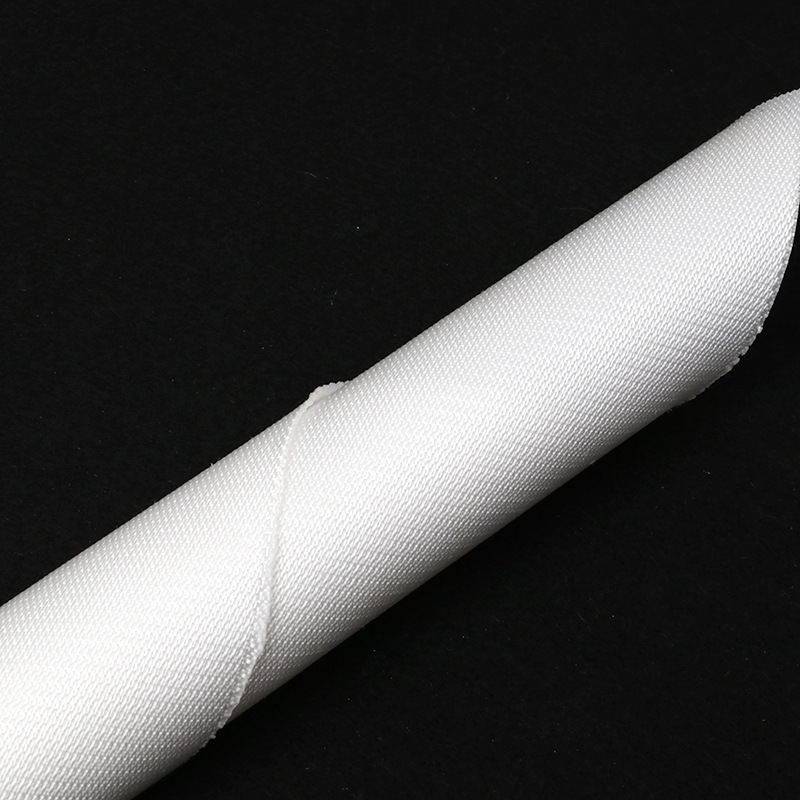

Processing - Thermal shrinkage

Finishing - Calendering

The color of the canvas is White

The color of the adhesive impregnation is Orange

The material is polypropylene, the canvas is made of TAMFELT fabric (VIRNT0420 multifilament), article (GOST) – PPT 3S/2K, mandatory adhesive impregnation – PRIMAL EKO. Complete with canvases, the mandatory presence of locks is 1,000 pieces. ISO 9001-2008 manufacturer's quality certificates and certificate of origin – originals are required. The cut of the canvas is laser, without eyelets.

1.Good material, durable Acid resistance, alkali resistance, corrosion resistance, excellent elasticity, good material and durability

2.Lathe sewing The cloth pattern is clear, flat, stable in size and not easy to deform

3.Strong wear resistance High density but good permeability, easy to stretch

Features

1. Made of 100% pure polypropylene fiber;

2. Even fiber pore size for efficient filtration;

3. Excellent chemical stability, acid and alkali resistance, and a wide range of applications;

4. Comply with the international regulations on food grade materials;