How to choose the appropriate titanium fiber sintered felt in the filter system?

1. There is no high content in the filtration material, and the effect of titanium fiber tie -sienal felt is better.

2. Pay attention to the pressure of titanium fiber sintered felt.

Be sure to control within 0.3MPa, otherwise regeneration is more difficult.

3. Titanium fiber sintering felt can only be separated by solid fluid, remove mechanical particles, and cannot remove various metal ions.

4. Filtering materials cannot contain high concentration of chloride ions.

5. Select the appropriate accuracy of titanium fiber sintering felt. The pore diameter of the selected titanium fiber sintering felt is far less than the diameter of the solid impurities to prevent the solid impurities from entering the inner hole of the titanium fiber sintering felt wall.

6. There are many ways to regenerate titanium fiber sintering felt. For different impurities, different regeneration methods need to be selected, such as: air, steam anti -blow, anti -washing, positive washing, pickling, alkaline washing, ultrasonic cleaning and other methods.

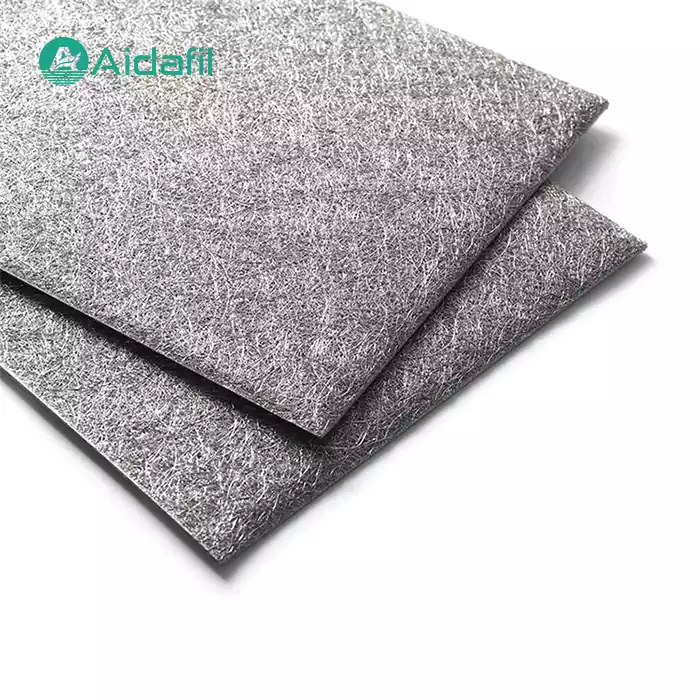

Titanium fiber felt characteristics:

Uniform aperture distribution

Strong corrosion resistance

Good water permeability

High pore rate

Good heat dissipation

High current density

Low voltage

Stable performance, long service life

Application of Titanium felt:

Titanium felt for Liquid/ Gas diffusion layer (LGDL)

Hydrogen absorber and Hydrogen-rich water dispenser

Diffusion layer of hydrogen fuel cell stack

Hydrogen production by PEM water electrolysis

The market applications of titanium felt are not so wide, most of which are still in the test stage.

I have an Israeli customer who has just purchased titanium felt samples for electrolytic grooves. He informed that it is still in the test stage. If the titanium felt to meet the requirements in the later period, the annual usage in the later period is very large, and it is expected to purchase more than 1,000 square meters a year.