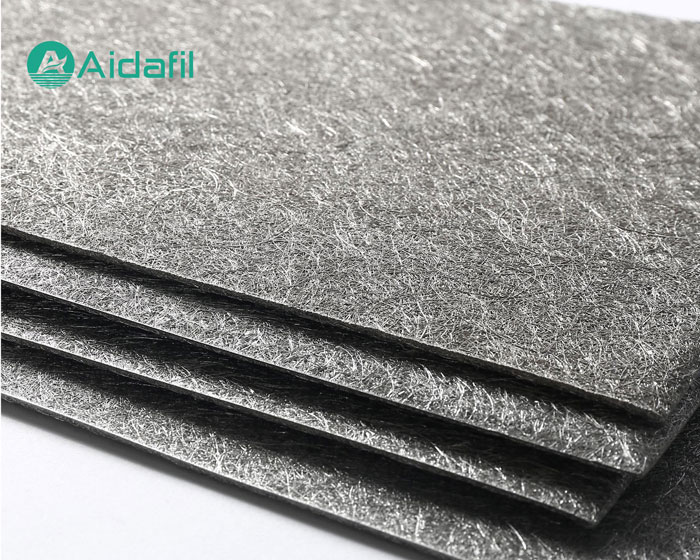

The metal fiber sintered felt is made of metal fibers with a diameter of micrometer through non-woven paving, overlapping and high-temperature sintering. Multi layer metal fiber felt forms a pore gradient from different pore size layers, which can control the extremely high filtration accuracy and greater pollutant holding capacity than single layer felt. It has three-dimensional network, porous structure, high porosity, large surface area, and uniform pore size distribution. Therefore, the stainless steel sintered felt effectively overcomes the defects of the metal mesh that is easy to block and wear. The utility model makes up for the shortcomings of the powder filter products, such as friability and small flow, and solves the problems of the filter paper and filter cloth that are not resistant to temperature and pressure.

Main features

1. Sintered metal felt has excellent mechanical strength with excellent uniform distribution, high permeability.

2. It is not only resistant to corrosion and high temperature, but also can be welded, folded and reused.

3. Sintered metal felt is an ideal high efficiency filter medium, which is suitable for working under high temperature, high pressure difference and high corrosion conditions.

4. Micron level, 3-100 μ m, dimensional accuracy can be provided as required.

Main application

1、 Filtration and purification of various polymer melts in chemical fiber and film industries.

2、 Filtration of various high-temperature and corrosive liquids in the fields of petroleum, chemical industry and power plant.

3、 Precision filtration of various hydraulic oil and lubricating oil for mechanical equipment.

4、 Clarification of various liquids in pharmaceutical, biological, beverage and other industries.

5、 Gas filtration and heat dissipation.

Advantages

1. Features extremely high porosity: - High flow rate: 20 times higher than other media types

2. Long service life

3. Low pressure drop: the high porosity of our metal fiber media allows very low pressure drop (thus reducing energy costs), even at high filtration rates

4. Easy to clean: The open structure of porous metal media allows you to conduct in-situ cleaning by backwashing or backwashing.

5. High strength: the sintering process produces strong fiber bonding to ensure high strength filter media.

Customer case

Australian customers purchase metal sintered felt for vacuum pump protection filter. As a good prefilter material, this product has excellent filtration performance and can better save costs for customers, protect vacuum pump filters, and can specially produce reinforced, thickened, protective mesh and other specifications according to user requirements.