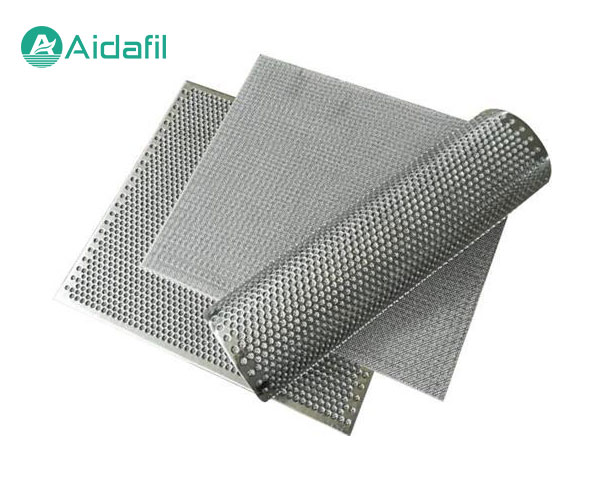

The punching plate composite sintering screen is composed of a punching plate made of standard material 304 and several layers of square mesh (or dense mesh). The number of layers and the number of meshes constituting the mesh are determined according to different use conditions and purposes. Because the pressure resistant framework is sintered with the filter screen as a whole, it has more excellent backwashing effect and low pressure drop loss. It has been widely used in water treatment, beverage, food, metallurgy, chemical industry and pharmaceutical industry.

Main features

1. Large range of filtering precision: from 1-10 microns, all have reliable filtering performance.

2. Stable filtering accuracy: due to the protection of upper and lower layers of wire mesh and the sintering process of diffusion and solid melting, the mesh of the filter layer is not easy to deform.

3. Good strength: because the fourth and fifth layers are used as supports, it has high pressure resistance and mechanical strength.

4. Easy to clean: because the surface filter material is used, it is easy to clean, especially suitable for backwashing.

5. High temperature resistance: it can withstand the high temperature of 480 ℃.

6. Corrosion resistance: Because SUS316L material is used, the corrosion resistance is high.

7. Easy processing: suitable for cutting, bending, stamping, stretching, welding and other processing conditions.

Main application

1. Materials used for dispersion cooling in extremely high temperature environment.

2. The application of uniform gas in powder industry and fluidization plate in steel industry; Orifice plate material for gas distribution fluidized bed; It is used in the fluidization and dense phase conveying system of pulverized coal injection for blast furnace.

3. Filtering, washing and drying of materials in the pharmaceutical industry; Catalyst support grid.

4. It is used for filtering polyester, oil products, food and beverage, chemical fiber products, water treatment and gas filtering.

Advantages

1. The mesh channel is smooth and has excellent backwashing regeneration function. It can be used repeatedly after cleaning. It is a very suitable choice for the operation program that needs to achieve continuity and automation.

2. Punched plate composite mesh has high mechanical strength and good pressure resistance. It is supported by punched plate during reuse and has good rigidity. It can be used as decentralized cooling material in high temperature environment, or even used as fluidizing plate in steel industry. 3. The filtering effect is good, and the work is relatively stable. At the same time, the punched plate composite plate is resistant to high temperature and corrosion. In the pharmaceutical industry, you can come here for boring filtering, washing, drying and other work.

4. The punching plate composite screen is easy to clean and not easy to deform, so it does not need to invest too much manpower, which can effectively reduce the manufacturer's low cost investment.

Customer case

American customers purchased a batch of perforated plate composite sintering screens for the filtration, washing and drying the materials required by pharmaceutical companies. It has the characteristics of high flow and is easy to clean, which greatly meets the working conditions of the customer company, saves costs for customers, and has been unanimously recognized by customers.