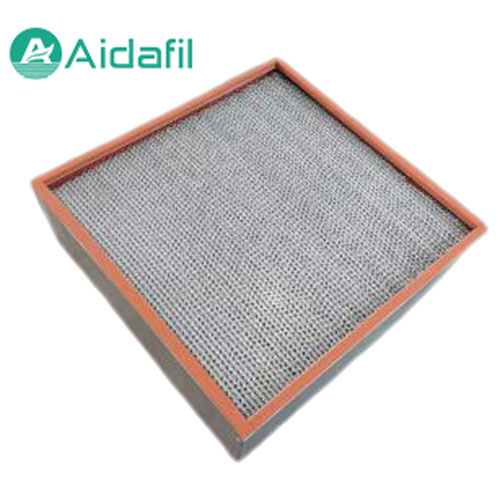

Plate and frame filter is widely used in iron and steel, electronics, chemical industry, automobile, environmental protection, electric power and other industries. It is the inlet filtration equipment of centrifugal compressor filtration room. And the dedusting, degreasing and coarse filtration of various air conditioning systems. It has large dust capacity and long service life.

Main features

1. The filter plate of plate frame filter adopts threaded structure. Different filter materials can be replaced according to the requirements of different filter media and production processes (primary filtration, semi fine filtration and fine filtration). The purpose of aseptic filtration can be achieved by directly using micro porous filter membrane. Users can also reduce or increase the number of filter layers according to the size of the filter volume to make it suitable for production needs.

2. All sealing parts of plate and frame filter adopt silicone rubber sealing ring, which is high temperature resistant, non-toxic, no leakage and good sealing performance

3. The plate and frame filter adopts quick installation connection, which is convenient for disassembly and cleaning. The plate and frame filter has large filtering area, large flow and wide application range, so it is widely used in pharmaceutical, chemical, food and other industries. It is applied to the filtration of injection liquid in pharmaceutical factories, and the effect is very good.

4. The filter plate adopts flat thread mesh shape, with advanced structure, no deformation and easy cleaning, which can effectively increase the service life of various filter membranes, so as to reduce and save production cost. The plate frame filter is equipped with stainless steel infusion pump, which has small motor and low power consumption.

5. Corrosion resistant and durable.

Advantages

1. Solid structure, stable filtering effect and long service life;

2. Strong, efficient and easy to handle;

3. Low initial resistance;

4. Stable filtration efficiency;

5. The fiber is treated by special needle rolling method to form a gradual layer structure, so that the filter has the characteristics of low pressure loss, high dust collection and long service life.

Case study

In May, US client ordered 600 pcs this type air filters used in marine project. Specification is like following:

Model AF 592-592-292,

Air volume: 3000/125 cbm/hr

the efficiency: >85%

Frame material: galvanized steel

Seal glue: glass fiber media

Separation: aluminum membrane

Filter media: HV Filter paper

Max. working temp: 80 ℃

Max. working humidity: 80%

After installed, the air filter function well, with large flowing rate, low resistance and high dirt holding.