1. Description

The hydraulic oil filter element is an indispensable part of the pipeline series of the conveying medium. It is usually installed in the inlet filter of the hydraulic system to filter out metal particles and contaminants in the fluid medium and to protect the normal operation of machinery and equipment. The application range of hydraulic oil filter elements is very wide, covering almost all industries: steel, electric power, metallurgy, shipbuilding, aviation, paper making, chemical industry, machine tools and construction machinery, construction machinery and other fields.

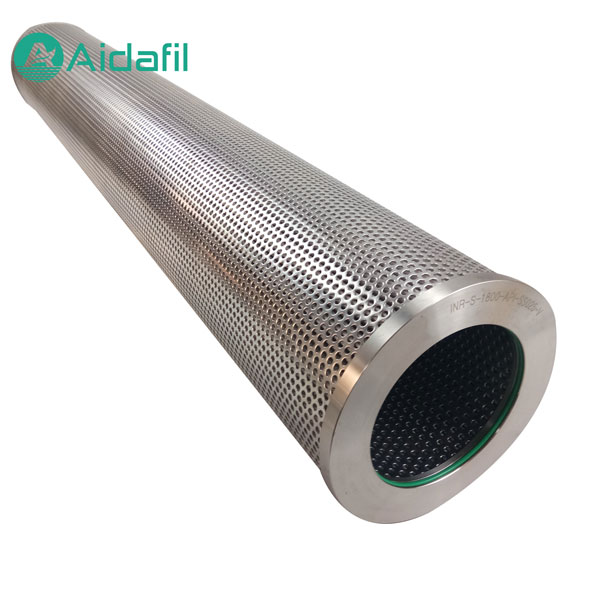

The stainless steel mesh hydraulic oil filter element INRS1800APISS025V produced by AIDA is mainly used for oil filtration in hydraulic system. It is used to filter out particulate debris and rubber impurities in the hydraulic system to ensure the cleanliness of the hydraulic oil, so that the hydraulic system can operate normally.

2. Filter Media Characteristics

The media that we produce in the filter INRS1800APISS025V Stainless Steel Wire Mesh and offers excellent resistance to temperature and corrosive fluids. This type of media is used extensively throughout the chemical, food and beverage, mining, and pharmaceutical industries. With its square aperture, high-flow through rate and relative open area, Stainless Steel Wire Mesh filters experience relatively low pressure drops during filtration.

Features:

Corrosive resistant

Highest temperature rating offered

Cleanable in some applications

3. Quality Test Standard

ISO 2941------Collapse & Burst Resistant

ISO 2942------Fabrication & Integrity Test

ISO 2943------Material Compatibility with Fluids

ISO 3723------ End-to-end compliance test

ISO 3724------Flow Fatigue Characteristics

ISO 3968------Pressure Drop & Flow Rate

ISO 4572------Multi-pass Performance Testing

4. Applications

1.Metallurgy: It is used for the filtration of the hydraulic system of rolling mills and continuous casting machines and the filtration of various lubricating equipment.

2. Petrochemical: separation and recovery of products and intermediate products in the process of oil refining and chemical production, and particle removal and filtration of oilfield well injection water and natural gas.

3. Textile: Purification and uniform filtration of polyester melt in the process of drawing, protection and filtration of air compressors, and degreasing and dehydration of compressed gas.

4. Electronics and pharmaceuticals: pre-treatment and filtration of reverse osmosis water and deionized water, pre-treatment and filtration of cleaning solution and glucose.

5. Thermal power and nuclear power: gas turbine, boiler lubrication system, speed control system, bypass control system oil purification, water supply pump, fan and dust removal system purification.

6. Mechanical processing equipment: papermaking machinery, mining machinery, injection molding machine and large-scale industrial machinery lubrication system and compressed air purification, dust recovery and filtration of tobacco processing equipment and spraying equipment.

7. Railway internal combustion engine and generator: filtration of lubricating oil and oil.

8. Automobile engines and construction machinery: air filters, oil filters, fuel filters for internal combustion engines, various hydraulic oil filters, diesel filters, and water filters for construction machinery, ships, and trucks.

9. Various lifting and handling operations: from construction machinery such as hoisting and loading to special vehicles such as fire fighting, maintenance and handling, ship cranes, windlasses, blast furnaces, steel-making equipment, ship locks, opening and closing devices for ship doors, Elevating orchestra pits and stages in theaters, various automatic conveying lines, etc.