Designed for the filtration of high-viscosity liquid, it could remove more impurities from water or a series of viscous liquid, and scrape impurities off the inner surface of strainer at high speed.

In comparison, it was always more frequently for traditional self-cleaning filters to get clogged up when filtering viscous material and soft impurities, with the result of higher and higher costs. Frequent manual cleaning, serious waste of consumables and heavy work have been caused consequently.

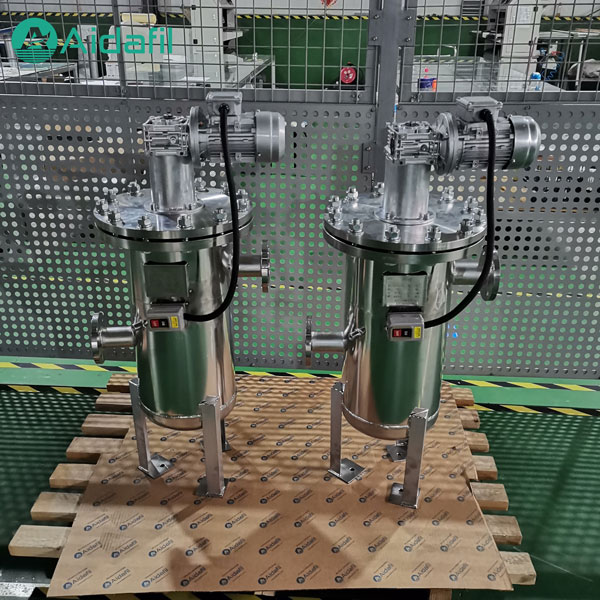

To solve the above problems, the way of self cleaning was taken in the AIDA electric internal scraper self-cleaning filter. It shows obvious advantages and greater efficiency in the performance of filtering poor-quality water; adhesive; resin; oil; polymer; coating material, etc.

The strainer could maintain cleanliness after regularly automatic self-cleaning. And the amount of wasted material could decrease, owing to the expelled waste liquid which contains a high concentration of impurities.

Technical data:

Precision |

30-1500μm |

Temperature |

0-200℃ |

Pressure |

1.0MPa |

Filtration area |

0.14m²-1.45m² |

Advantages:

1. Horizontal rotary scraping: which could scrape the impurities directly.

2. Simple structure: it is easy to (dis)assembly the machine and clean the inner place. The strainer could be taken out after taking down the scrapers.

3. Fully automatic operation: which could finish the online filtration continuously, instead of manually replacing or cleaning.

4. Reduction in cost of consumables and environmental treatment: because there will be no one-time abandoned consumables.

5. Minute amount of pressure damage: which will lead to a regime flow and let production technology remain stable hour after hour.

6. Fully enclosed filtration: which would be beneficial to the security of production and the health of workers, by preventing the leakage of dangerous materials.

7. Reduction of wasting high-value materials: which could let the high-value materials be recycled from the expelled waste liquid with a high concentration of impurities.

Applications:

Industries: Petrochemical industry, fine chemical industry, oil industry, water treatment, paper making, etc.

Types of liquid: adhesive; resin; oil; coating material; polymer; citric acid; fermentation broth; chitosan; cosmetics; gel; silicone solution; soap; sorbitol; steroids; grain syrup; wet auxiliary; paints; lubricants; rubber; ethanol(alcohol); churning oil; edible oil; high-temperature oil; fruit juice; diesel oil, etc.