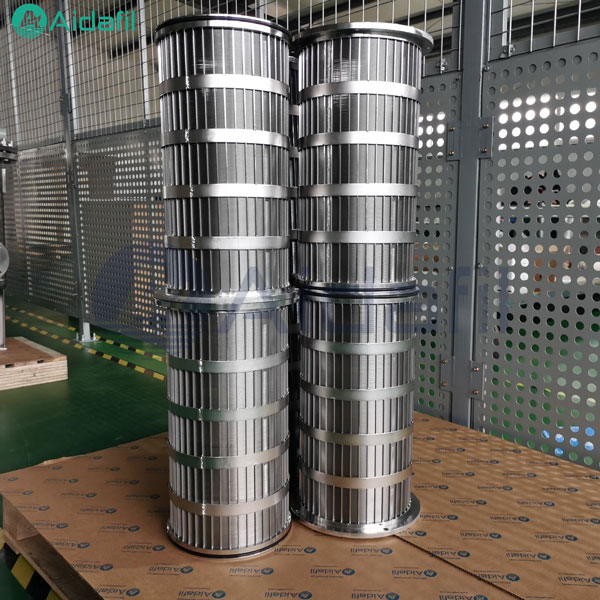

Wedge wire filter element inside of automatic back-washing filters

What operating precision range is available for wedge wire filter element?

The precision between 25 and 800 microns could be reached.

Wedge net: up to 2800 (wedge wire) x 4500 mm

The wedge wire filter element is welded by a wedge-shaped stainless steel wire and a stainless steel support bar. Those constant, high-density and uniform gaps formed by the metal wire which is arranged in a circular form provide a very effective support for the entrance’s area and non-obstruction of the sieve tube, and avoid the high-density accumulation of settling. As a result, the great improvement of production efficiency and a longer service life could be ensured.

How many kinds of materials could be used for wedge wire filter element?

There are almost 6 choices, Including stainless steel 304, 316, 316L, Hastelloy, copper, aluminum alloy and so on. The length of service life, the level of intensity and hardness are both depending on raw materials.

Which part of the hydraulic system is wedge wire filter element usually located in?

The form of wedge wire filter element is regarded as the surface filter, for which its first layer is smooth and its gaps are in the shape of bar.

It has been widely used into the fluid filtration in various industries like chemical, petrochemical, beverage, pharmaceutical, biotechnology, water treatment, solid-liquid separation and so on, especially installed as a filter element in various forms of automatic filters such as automatic back-washing filters, scraper self-cleaning filters, scraper self-cleaning filters and suction self-cleaning filters.

How long does it take to use up a wedge wire filter element?

The length of service life would vary with specific configuration levels. However, this kind of filter elements has been seized of its own advantages in durability, owing to the full-process welding which leads to strictly continuous integrity of products and a desired size of gaps.