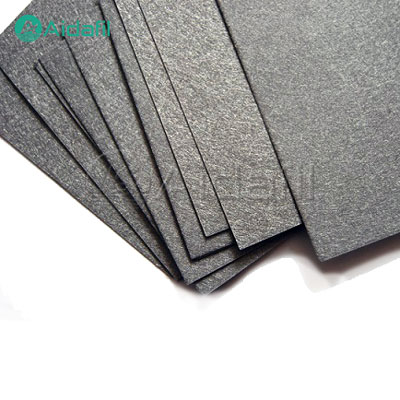

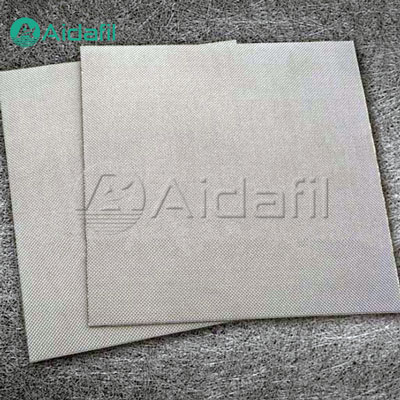

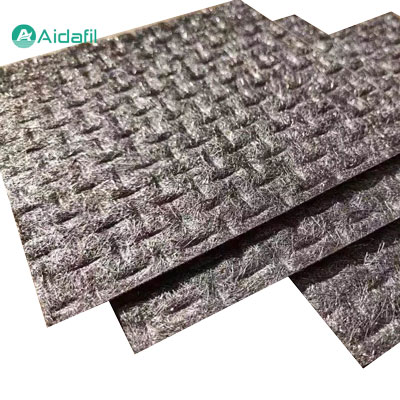

Corrosion resistant metal wire mesh filter with low temperature methanol washing

Model:Customizable

Precision:2μm -500μm

Product Details

The filter for low temperature methanol washing is mainly used to filter solid impurities such as iron sulfide and pulverized coal. There are two kinds of methanol filter, one is poor methanol filter and the other is methanol rich filter.

In the field of coal chemical industry, low temperature methanol washing process plays an important role. Whether it is the direct liquefaction of coal, indirect liquefaction, or coal gasification, most of them must have gas purification process. However, the low-temperature methanol cleaning process is undoubtedly the most competitive and mature gas purification technology at present. It has been widely used in ammonia synthesis, methanol synthesis and other carbonyl synthesis, urban gas, industrial hydrogen production and natural gas desulfurization and other gas purification units. Especially for the purification of syngas from coal (coal water slurry) or slag (heavy) oil, the effect of this method is better. In China, coal and residuum are used as raw materials. This technology is widely used in large-scale ammonia synthesis and methanol synthesis plants.

It is a physical absorption method to remove acid gas from raw gas by using cold methanol as absorbent solvent at low temperature and the excellent characteristic of methanol's great solubility to acid gas (CO2,H2S,COS et al.) at low temperature. Low temperature methanol washing process is the most economical and high degree of purification technology recognized at home and abroad. It has the characteristics that other desulfurization and decarburization technology can not be replaced, such as: good quality of purification gas, high degree of purification. It has the characteristics of selective absorption of H _ 2S _ 2O _ s and CO2, cheap and easy to obtain solvent, low energy consumption, low operating cost, stable and reliable production, etc.

In the field of coal chemical industry, low temperature methanol washing process plays an important role. Whether it is the direct liquefaction of coal, indirect liquefaction, or coal gasification, most of them must have gas purification process. However, the low-temperature methanol cleaning process is undoubtedly the most competitive and mature gas purification technology at present. It has been widely used in ammonia synthesis, methanol synthesis and other carbonyl synthesis, urban gas, industrial hydrogen production and natural gas desulfurization and other gas purification units. Especially for the purification of syngas from coal (coal water slurry) or slag (heavy) oil, the effect of this method is better. In China, coal and residuum are used as raw materials. This technology is widely used in large-scale ammonia synthesis and methanol synthesis plants.

It is a physical absorption method to remove acid gas from raw gas by using cold methanol as absorbent solvent at low temperature and the excellent characteristic of methanol's great solubility to acid gas (CO2,H2S,COS et al.) at low temperature. Low temperature methanol washing process is the most economical and high degree of purification technology recognized at home and abroad. It has the characteristics that other desulfurization and decarburization technology can not be replaced, such as: good quality of purification gas, high degree of purification. It has the characteristics of selective absorption of H _ 2S _ 2O _ s and CO2, cheap and easy to obtain solvent, low energy consumption, low operating cost, stable and reliable production, etc.

Related Products

Inquiry

Please kindly leave your detailed information. We will get in touch with you as soon as possible after receiving your message.