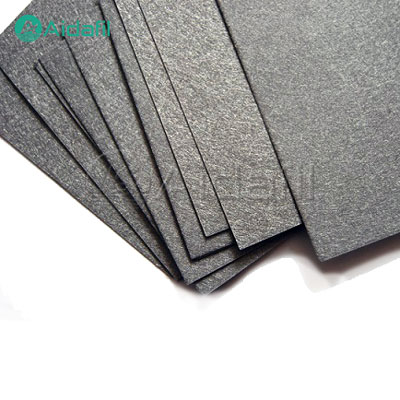

Manufacturer supply stainless steel sintered fluidized plate

Precision:1-100um

Product Details

Air fluidization plate, blast furnace fluidized plate for coal injection, air amplifier, air boiling plate, gas distribution plate

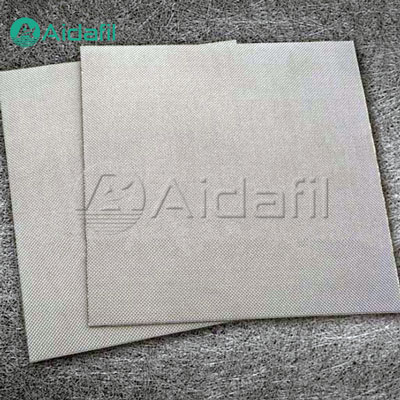

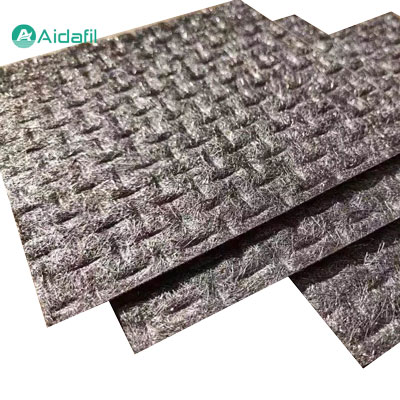

Air fluidized plate (also called air amplifier, air boiling plate), high-performance stainless steel sintered net as filter material. For coal ash recovery and dust filtration in power plants, there are a variety of product specifications and materials for users to choose. The sintered mesh fluidized plate is a new filter material with high mechanical strength and integral steel properties, which is made of multi-layer stainless steel wire mesh through special lamination and vacuum sintering. Fluid distribution control, powder material transport and fluidized bed operation have been widely used in petrochemical, metallurgical machinery, energy protection, aerospace, medicine and other industries, especially in the flow state. Chemical bed technology is an important means of mass transfer, heat transfer, mixing and chemical reaction in production process. Among them, the control of operating gas distribution requires porous orifice material. However, most of the fluidized plates used at present are ceramic fluidized plates and filter cloth. Because of the problems in structure and material, the permeability is poor, it is difficult to control the flow resistance, the air consumption is large, the effect is poor, and the service life is short.

The stainless steel sintered fluidized plate made by our company has uniform pore distribution, ranging in size from several microns to hundreds of microns, with equal pressure drop distribution, high mechanical strength, high heat resistance, strong corrosion resistance, and widely used for rectifying and powder conveying. Functional areas such as air dispersing, drying, cooling, immersion, impedance and other functional requirements such as blast furnace pulverized coal injection fluidization and dense phase conveying system, catalyst support barrier, ion exchange resin regeneration, fluidized bed, air bearing and thrust bearing, ventilation device, Aeration device, air float roller.

The characteristics of 1200'1000mm thickness 2-12mm stainless steel sinter mesh fluidized plate are as follows:

1, high porosity, uniform airflow distribution, stable control characteristics of permeability and flow resistance,

2, can be designed according to the needs of customers,

3, high mechanical strength, High rigidity, easy installation and maintenance;

4, good effect of mass transfer, heat transfer and fluidization, high efficiency and low air consumption;

5, little residual amount when removing granular objects, easy to clean;

6, easy processing, forming, good weldability;

7, high temperature resistance, corrosion resistance, applicable to a wide range of environment;

8, operation flexibility is large Convenient process adjustment, can eliminate breakdown short-circuit and blocking and other faults, long service life.

Air fluidized plate (also called air amplifier, air boiling plate), high-performance stainless steel sintered net as filter material. For coal ash recovery and dust filtration in power plants, there are a variety of product specifications and materials for users to choose. The sintered mesh fluidized plate is a new filter material with high mechanical strength and integral steel properties, which is made of multi-layer stainless steel wire mesh through special lamination and vacuum sintering. Fluid distribution control, powder material transport and fluidized bed operation have been widely used in petrochemical, metallurgical machinery, energy protection, aerospace, medicine and other industries, especially in the flow state. Chemical bed technology is an important means of mass transfer, heat transfer, mixing and chemical reaction in production process. Among them, the control of operating gas distribution requires porous orifice material. However, most of the fluidized plates used at present are ceramic fluidized plates and filter cloth. Because of the problems in structure and material, the permeability is poor, it is difficult to control the flow resistance, the air consumption is large, the effect is poor, and the service life is short.

The stainless steel sintered fluidized plate made by our company has uniform pore distribution, ranging in size from several microns to hundreds of microns, with equal pressure drop distribution, high mechanical strength, high heat resistance, strong corrosion resistance, and widely used for rectifying and powder conveying. Functional areas such as air dispersing, drying, cooling, immersion, impedance and other functional requirements such as blast furnace pulverized coal injection fluidization and dense phase conveying system, catalyst support barrier, ion exchange resin regeneration, fluidized bed, air bearing and thrust bearing, ventilation device, Aeration device, air float roller.

The characteristics of 1200'1000mm thickness 2-12mm stainless steel sinter mesh fluidized plate are as follows:

1, high porosity, uniform airflow distribution, stable control characteristics of permeability and flow resistance,

2, can be designed according to the needs of customers,

3, high mechanical strength, High rigidity, easy installation and maintenance;

4, good effect of mass transfer, heat transfer and fluidization, high efficiency and low air consumption;

5, little residual amount when removing granular objects, easy to clean;

6, easy processing, forming, good weldability;

7, high temperature resistance, corrosion resistance, applicable to a wide range of environment;

8, operation flexibility is large Convenient process adjustment, can eliminate breakdown short-circuit and blocking and other faults, long service life.

Related Products

Inquiry

Please kindly leave your detailed information. We will get in touch with you as soon as possible after receiving your message.