The MCC1401 filter element can be used with two basic types of media: Epocel - a resin-impregnated cellulose, and Ultipor - a resin-bonded fiberglass. These specially designed absolute rated media are available in different grades with specified removal efficiencies, providing up to 54 square feet of effective filtration surface area, ensuring a long service life. Please check the elements and housings sheet as below:

Table 1. MCC1401 Elements – Performance Characteristics

| Cartridge Part Number | Liquid Removal Rating | Gas RemovalRatingPercentRemoval6 | EffectiveArea3 | MediaDescription | ElementPressure | AqueousDrop | |||

| Percent Removal | 99.98%1 | 99% | 90% | psid/gpm | mbar/lpm | ||||

| Beta 2, 5 | 5000 | 100 | 10 | Sq. ft. | |||||

| MCC1401U2-20ZH13 | (2) (4) | 2.0 | 0.8 | 0.3 | >99.99 at0.3 micron | 54 | Ultipor ResinBonded Glass | 0.021 | 0.382 |

| MCC1401U6-40ZH13 | (2) (4) | 2.5 | <1.0 | <1.0 | >99.98 at0.3 micron | 53 | Ultipor ResinBonded Glass | 0.0015 | 0.027 |

| MCC1401E100H13 | (2) (4) | 10.0 | 5.0 | <2.0 | 95.7 at0.3 micron | 37 | Epocel ResinImpregnatedCellulose | 0.005 | 0.091 |

| MCC1401E280H13 | (2) (4) | 23.0 | 16.0 | 8.0 | 45 | Epocel ResinImpregnatedCellulose | 0.002 | 0.036 | |

| MCC1401E500H13 | (2) (4) | 50.0 | 44.5 | 27.0 | 45 | Epocel ResinImpregnatedCellulose | 0.0017 | 0.031 | |

Table 2. Standard MCC1401 Housings – Carbon Steel, Rated at 285 psig/19.6 bar and 100˚F/37˚C

| Part Number | Number of Filters | Nominal Vessel Diameter | Inlet/Outlet Flange Size | Housing Height | Housing Weight (empty) | Housing Weight (full) |

| in/mm | in/mm | in/mm | lb/kg | lb/kg | ||

| 1MCC0603F1285 | 1 | 6.625 / 168.3 | 3 / 76.2 | 54.25 / 1378 | 200 / 91 | 250 / 113 |

| 4MCC1004F1285 | 4 | 10.75 / 273.1 | 4 / 101.6 | 59 / 1498.6 | 440 / 199 | 585 / 265 |

| 5MCC1206F1285 | 5 | 12.75 / 323.9 | 6 / 152.4 | 64 / 1625.6 | 680 / 308 | 925 / 419 |

| 9MCC1608F1285 | 9 | 16 / 406 | 8 / 203.2 | 84 / 2133.6 | 1070 / 485 | 1570 / 712 |

| 15MCC2010F1285 | 15 | 20 / 508 | 10 / 254 | 93 / 2362.2 | 2000 / 907 | 2750 / 1247 |

| 19MCC2412F1285 | 19 | 24 / 609.6 | 12 / 304.8 | 110 / 2794 | 2300 / 1043 | 3500 / 1587 |

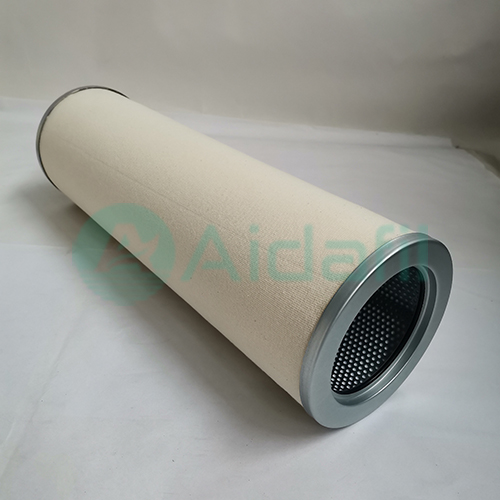

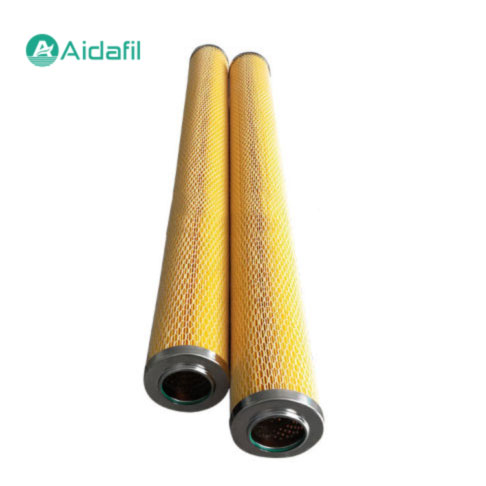

Filter Media Characteristics

Epocel Filter Cartridges: This filter media consists of resin-impregnated cellulose media. The resin impregnation technique is used to lock the cellulose fibers in place, preventing bending or shifting, which can change the size of the flow channel and reduce removal efficiency. Epocel media is compatible with many fluids, including fresh and produced water, acids, solvents, brines, hydrocarbons, alcohols, and more. Epocel filter cartridges are available in grades ranging from 10 microns to 50 microns absolute.

Ultipor Cartridges: These cartridges are made with resin-bonded fiberglass media for rugged durability. The inert resin bond ensures that the filter does not undergo media migration and establishes a permanent, fixed pore structure that prevents unloading of captured contaminants. Due to its efficient filtration area and optimized construction, Ultipor filters offer high dirt holding capacity, long life and low cost per gallon of treated fluid

Operating Characteristics

MCC1401 cartridges are of pleated design, supported internally by a steel core and protected externally by steel endcaps, providing positive sealing via an internal O-ring. The maximum recommended changeout differential pressure is 60 psid/4.13 bar at 275˚F/135˚C.

Applications:

Removal of contaminants from natural gas pipelines at the inlet of the compressor station to avoid damage to the compressor and prevent wear of the cylinders and valves.

Prevent the injection of solid and liquid contaminants before the natural gas storage station.

Removal of contaminants from fuel gas lines in engines, power plants and pre-plants.

Removal of solid and liquid contaminants in front of the gas treatment station to prevent contamination of process equipment and poisoning of the catalytic bed.

Downstream of the reciprocating compressor to remove the lubricating oil carried in the air stream.

Prevent fracturing and sanding of desiccant and contamination of paraffin and asphaltenes before the solid desiccant bed.

Remove water and pipeline contaminants from the inlet gas stream at the dewatering and treatment station.

Related part numbers:

| MCC1401U2-20ZH13 | MCC1401E500H13 | 9MCC1206F1285 | MCC 1401J060 - H13 | MCC 1401E500- H13 | 52FC1734 | PS-220-LL-20-LB |

| MCC1401U6-40ZH13 | 1MCC0603F1285 | 15MCC2010F1285 | MCC 1401J100- H13 | PS-336-CC-40LB | PCHG-336 DN | DFN10-1410 |

| MCC1401U6-40ZH13 | 4MCC1004F1285 | 19MCC2412F1285 | MCC 1401E100- H13 | PS-336-CC-20LB | PCHG-336 HP | PCC30-1401 |

| MCC1401E280H13 | 5MCC1206F1285 | MCC 1401JO25- H13 | MCC 1401E280- H13 | 52CC1324 | F-1602 749 KF | PCG020-1401 |

-

substitute DuoToV 90/600 90/736 gas coalescing separator cartridge

-

wet gas coalescing cartridge DuotoV 90/180 90/279 replacement