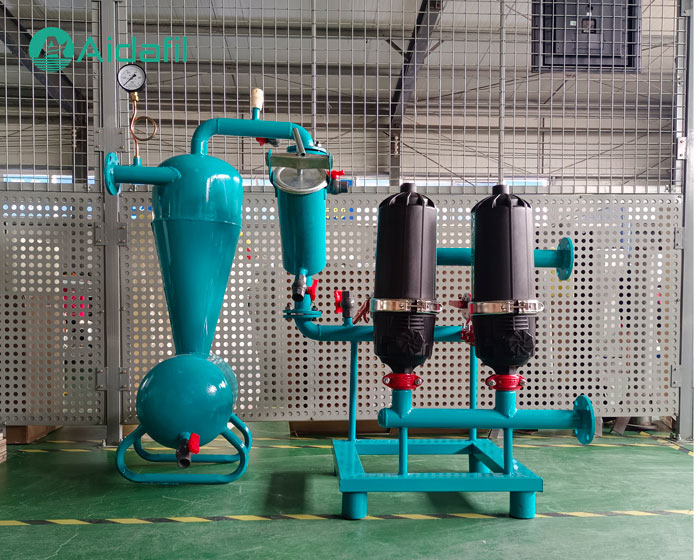

The Automatic back flush disc filter backflushes in only one station while the rest of the

equipment is in filtration stage. Filtration stage: The helix generates a centrifuge helical effect, which blocks particles in the

discs. Backflushing stage: The filtered water is introduced in the opposite direction, decompressing

the stacks of discs and making the backflushing. The solids expelled from the discs are evacuated by the drainage manifold. The filtration stage starts again with the compression of the discs.

One of my Malaysia client contact me this Monday. He needs three Units dics filter. He needs this machine to filter sand and dirt from cooling water. The flow rate is 50m3/h and 100m3/h. Micron needs 50um and 100um. After discussion with him. we recommended model ADLF02-2 and ADLF03-3 filters according to client request. inlet/outlet DN50, structure steel stainless steel and power 220V. I will contact him today later today. He is in meeting now. Will make contract for him soon.

We promise that he will like our machine and will build long term cooperation in future.

Pre: hydraulic filter element HP0394A25ANP01100

Next:Chile' new customer bought handle oil purifier for hydraulic oil filtration

Related News

- Indian new customer ordered 100m³/h Auto bag filters for wastewater treatment use

- E16KE(901522.0) Line filter

- South African customer purchased DN65 Stainless steel Duplex filters for food processing factory

- UAE customer order 100pcs 40μm basket strainer filter element for oil and gas company

- The Peru customer is considering AOP-1V-25 Vacuum Oil purifier procurement