The dust enters into the dust catcher through the dust hood, flow control valve, and dust removal pipeline; and the gas-solid seperation and gas-liquid seperation are done through the PTFE sintered filtration plate. The purified air is discharged from the air outlet of the upper box on the fan. The dust attached to the surface of the PTFE sintered plate is blown back by compressed air through the pulse valve. The dust removal control can be selected to work according to time, pressure difference or mixing mode, and the dust enters the ash hopper under the dust collector body. The dust attached to the surface of the PTFE sintered plate is backflushed by compressed air through the pulse valve. The dust removal control can be selected to work according to time, pressure difference or mixing mode of the two, and the dust enters into the dust hopper under the dust collector body. The bottom of the dust hopper of a single dust catcher is equipped with a screw conveyor, a dust discharge valve and a dust discharge port. The dust is discharged from the dust discharge port through the screw conveyor and the ash discharge valve.

Product advantages

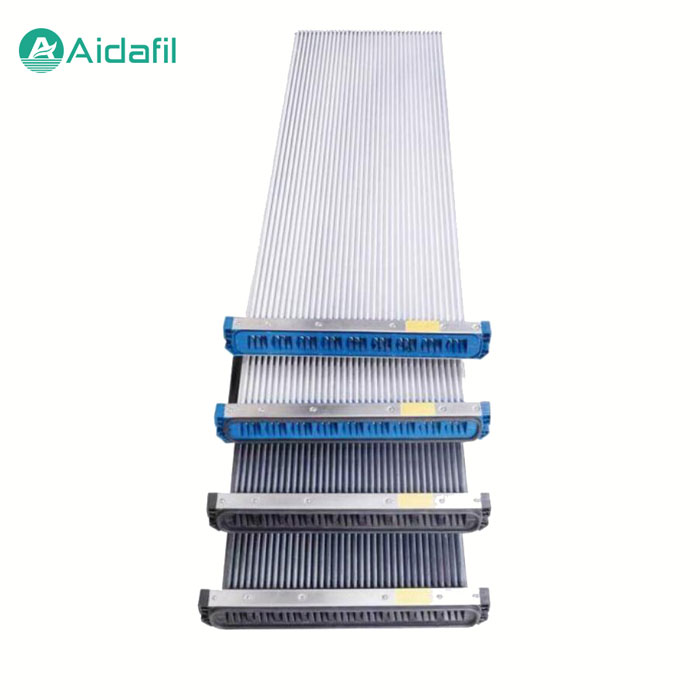

PTFE sintered plate: PTFE sintered plate is a "T" plate formed by one-time sintering without adhesive. The direction of backflushing is the same as that of falling ash, and it is installed vertically.

Also known as: "T" type PTFE sintered plate. Color: white, two sizes: 1480mm*470mm*50mm

1550mm*1 050mm*50mm.

The filtering area is 4.5m2 and 9m2 respectively. PTFE sintered plate has the ability to resist heavy metal clogging, excellent oil and water resistance, low resistance and long service life. Pulse valve: The specially imported large caliber pulse valve not only has a good dust cleaning effect, but also has a small volume, a large flow rate and a service life of more than 3 million times. The cleaning area of each pulse can reach 18m2 (the cleaning area of other small-diameter valves is 7.5m2), so the number of using this pulse valve is only 40%~50% of similar products. Therefore, the dust catcher has the characteristics of small volume, large filtering area, long-term use and convenient maintenance.

Product features

1. PTFE SINTERED PLATE MATERIAL AND MANUFACTURING FEATURES:

The material of the wave. type PTFE sintered filtration plate is composed of a variety of polymer compound powders, and the color is white. The manufacturing process does not use adhesives to bond and form the filter plate, but uses a method of forming and sintering these various polymer compounds at one time. At present, there are three main types of temperature resistance products,which are room temperature resistance 70°C,heat resistance 110°C and heat resistance 160°C. In addition, there are a wide range of anti-static PTFE sintered plate, acid and alkali resistant PTFE sintered plate and so on.

2. SHAPE CHARACTERISTICS OF PTFE SINTERED PL ATE:

PTFE sintered plate is "white trapezoidal plate". The external shape of the filter plate is characterized by a wavy shape like an accordion box. If they are unfolded into a plane, the surface area is equivalent to 3 times larger. "Trapezoid plate" means that the bottom of the wave (also the part where dust is easy to accumulate) is designed as the upper side of the trapezoid, so that it can be stressed on three sides,and it is not easy to be blocked during blowback. A piece of 470 (length) X50 (thickness) X1480 (height) white PTFE sintered plate, its surface area can reach 4.5m2, which is equivalent to the surface area of 6 national standard DMC type pulse dust collector filter bags (φ133X2000). The inside of the wave filter plate is divided into 9 or 18 cavities. In addition to considering the strength of the components, this design is important for the needs of aerodynamics. It can ensure that when the pulse airflow is reversed to clean the dust, it can be cleaned at the same time. Remove the dust adhering to the filter plate.