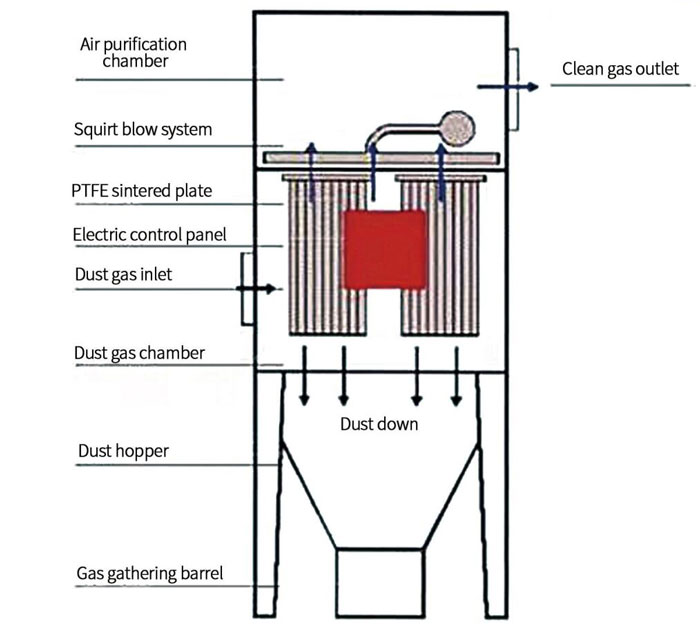

PTFE sintered plate dust catcher is one of the most advanced dust catcher in the world. It is generally installed on the negative pressure side of the fan. The dust catcher adopts the structure of lower air intake and upper air exhaust, so, it has an outer filter structure, it also has an integral filtration chamber. The dust-laden gas enters the middle box (dust-air box) through the air duct. When the dust-laden gas passes through the PTFE sintered plate from its outer surface, the dust is blocked on the PTFE coating on the surface of the PTFE sintered plate. When the dust on the surface of PTFE sintered plate increases, it is necessary to clean the filtration chamber, the opening and closing of the pulse valve is controlled through the control mechanism (timing or pressure difference), to blow the PTFE sintered plate, and the dust falls into the dust hopper under the action of air flow and gravity.The dust is transported away through the ash conveying device and the star-shaped ash discharge valve; then the purified gas flows through the pores of the PTFE sintered plate into the clean air box, and is finally discharged into the atmosphere through the chimney and the fan. The PTFE sintered plate dust catcher system includes:Main box, PTFE sintered plate, main air inlet and outlet pipeline, compressed air pipeline, ash cleaning system, ash conveying system, heat tracing and insulation system, operating platform, ladder, etc.

Equipment composition

1. Main box body of dust Catcher: including steel structure frame of dust collector body, box body and hopper.

2. PTFE sintered plate body: it is made of special polymer composite materials through high-temperature sintering and special treatment such as surface coating.

3. Inlet and outlet air duct: calculate and design the inlet and outlet air duct according to the design position, to ensure the basic balance of the uniform inlet and outlet air volume of the process. The air duct design must be convenient for each room maintenance.

4. Compressed air pipeline and air storage tank: meet the requirements of equipment for compressed air.

5. Dust cleaning system: advanced supporting solenoid valve device is adopted, which has continuous service life and reliable working performance. The whole device is placed and sealed inside the dust removal box. In case of humidity and dust, it can protect the solenoid valve, greatly reduce the failure of the squirt&blow system, to reduce the maintenance.

6. Dust remover and dust conveying system: Advanced dust conveying device, closed rotary star ash unloading valve, etc. are adopted. Continuous dust transportation and regular dust removal.

7. Heat tracing and insulation system: we adopt advanced and efficient electric heat tracing system. - Steam coil heat tracing system can be adopted according to the needs of users.