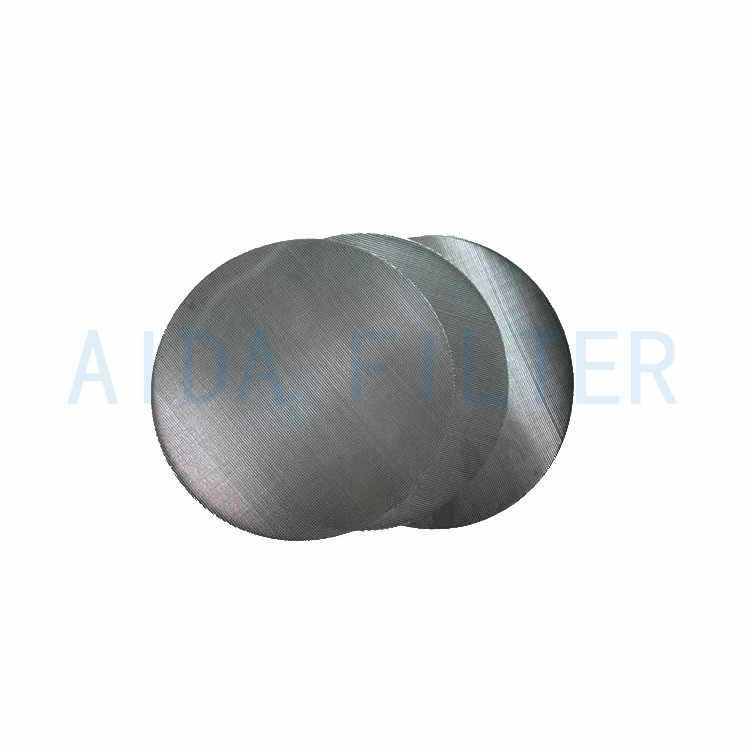

High performance stainless steel metal sintered Filter disc for chemical

Precision:1-200um

Product Details

The filter tray is an ideal filter element for filtering, washing and desiccating (abbreviated as three-in-one). The main filter material is made of multi-layer stainless steel sintered mesh, welded with flange to form a circular filter or a cone filter, mainly used in pharmaceutical, chemical, food and other three-in-one and two-in-one equipment, replacing the traditional filter cloth, with good rigidity and high strength. Long replacement period, easy cleaning, assembly sheet and other advantages. The filtering accuracy is 1 ~ 300 μ m. Diameter 100-3000 mm, filter disk structure and integral type.

The characteristics of sintered mesh filter plate are as follows:

1. Good rigidity, accurate filtration accuracy, can be washed repeatedly, long-term use,

2. Countercurrent cleaning effect is good, can be used repeatedly, long life (countercurrent water, filtrate, ultrasonic, melting, baking and other methods can be used to clean).

3. The maximum pressure difference is: 3.2MPa 4. Number of layers: 2 to 6

Sintered mesh filter plate specification: 1. Custom Sus punching plate sintering mesh 2. Material: SUS304SUS316L3. Precision: 1 to 200 microns

4. Temperature: -200-480 ℃. Dimensions: customizable

Application of sinter mesh filter:

1. Electronic industry: reverse osmosis water system pre-filtration, deionized water system pre-filtration.

2. Pharmaceutical industry: filtration of pharmaceutical, biological and plasma products, compressed air and gas filtration.

3. Food and Beverage Industry: mineral Water, Beverage, Juice, Liquor filter. 4. Chemical industry: organic solvents, ink filtration. 5. Petroleum industry: oil field water filtration. 6. Other: electroplating solution, metal cutting fluid, photoresist and magnetic medium filtration and other characteristics.

4. The application example of sinter net filter plate is as follows: 1. Mechanical industry of various hydraulic oil lubricating oil precision filtration; 2. Filtration and purification of various polymer melts in chemical fiber film industry, filtration of various high temperature corrosion fluids in petrochemical industry, filtration, washing and drying of materials in pharmaceutical industry; 3. The application of gas homogenization in powder industry, fluidized plate in iron and steel industry; 4. Explosion-proof electric apparatus, etc. Purification of high temperature flue gas in metallurgical industry. Filtration and recovery of catalyst; 7. Glass industry high-temperature exhaust gas, boiler, incinerator high-temperature exhaust gas filtration.

The characteristics of sintered mesh filter plate are as follows:

1. Good rigidity, accurate filtration accuracy, can be washed repeatedly, long-term use,

2. Countercurrent cleaning effect is good, can be used repeatedly, long life (countercurrent water, filtrate, ultrasonic, melting, baking and other methods can be used to clean).

3. The maximum pressure difference is: 3.2MPa 4. Number of layers: 2 to 6

Sintered mesh filter plate specification: 1. Custom Sus punching plate sintering mesh 2. Material: SUS304SUS316L3. Precision: 1 to 200 microns

4. Temperature: -200-480 ℃. Dimensions: customizable

Application of sinter mesh filter:

1. Electronic industry: reverse osmosis water system pre-filtration, deionized water system pre-filtration.

2. Pharmaceutical industry: filtration of pharmaceutical, biological and plasma products, compressed air and gas filtration.

3. Food and Beverage Industry: mineral Water, Beverage, Juice, Liquor filter. 4. Chemical industry: organic solvents, ink filtration. 5. Petroleum industry: oil field water filtration. 6. Other: electroplating solution, metal cutting fluid, photoresist and magnetic medium filtration and other characteristics.

4. The application example of sinter net filter plate is as follows: 1. Mechanical industry of various hydraulic oil lubricating oil precision filtration; 2. Filtration and purification of various polymer melts in chemical fiber film industry, filtration of various high temperature corrosion fluids in petrochemical industry, filtration, washing and drying of materials in pharmaceutical industry; 3. The application of gas homogenization in powder industry, fluidized plate in iron and steel industry; 4. Explosion-proof electric apparatus, etc. Purification of high temperature flue gas in metallurgical industry. Filtration and recovery of catalyst; 7. Glass industry high-temperature exhaust gas, boiler, incinerator high-temperature exhaust gas filtration.

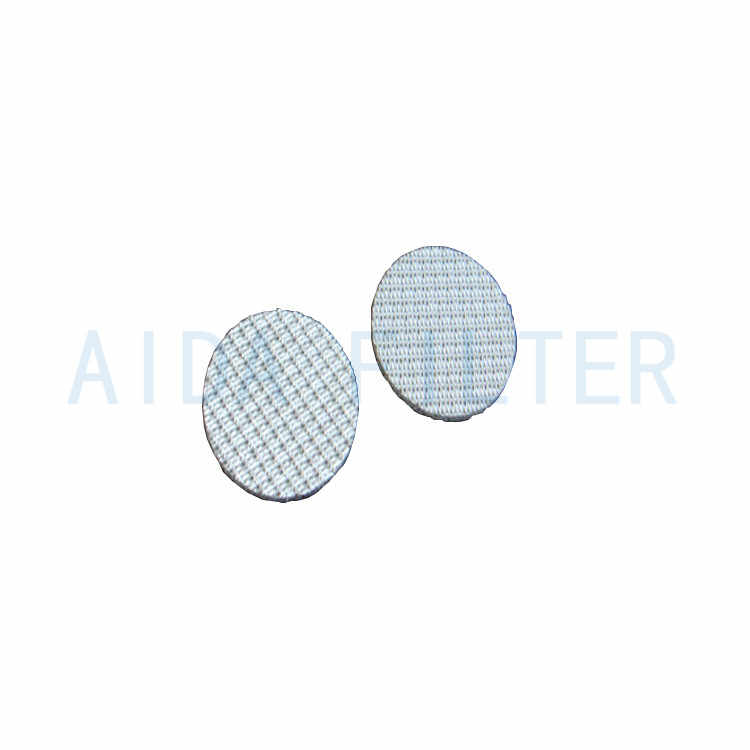

Related Products

-

Manufacturer direct supply sintered stainless steel filter disc for explosion-pr

-

High quality sintered stainless steel filter disc for flame proof

-

High quality sintered stainless steel filter disc for chemical industry

-

High quality sintered stainless steel filter disc for power plant

Inquiry

Please kindly leave your detailed information. We will get in touch with you as soon as possible after receiving your message.