Product Details

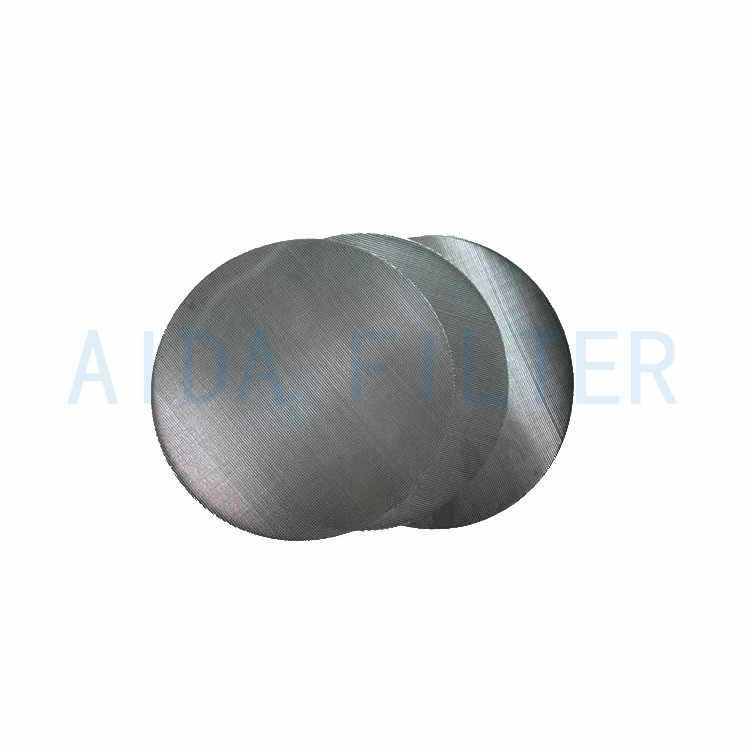

Multi-layer Sintered Woven Wire Mesh

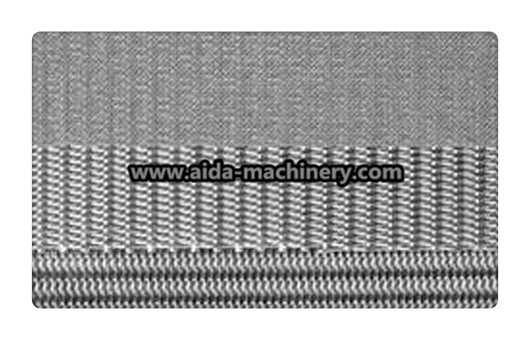

sintered multi—layer metal mesh is composed of laminated layers of wire cloth bonded special calendering and sintering in vacuum oven ,to create a new filter material with higher strength and rigidity. it is interlaced mesh forms an uniform and ideal filtration structure ,As a new filter material .it not only overcomes the disadvantages of ordinary metal mesh ,such as lower strength, poor rigidity, unstable hole shapes, but has excellent performance such as high precision and strength ,efficient flow restriction mechanical and resistance to abrasion, heat and cold by reasonably arranging its porosity permeability and strength .therefore ,its total performance has obviously advantages than sintered powder, ceramic, fiber cloth, other filter material.

our sintered mesh has been widely used in many industries such as aerospace,aviation,petroleum,chemical,metallurgy,machining,pharmaceutical,food,synthetic fiber ,film, environment al-protection industries in respect of filtration and purification ,gas-solid, liquid-solid and gas –liquid separation. cooling, gas distribution, fluidization bed ,gas samping collection, shock reducing ,sound attenuation, inflaming retarding.

Main application:

1 distribution and cooling material in high temperature

2 material used for gas distribution and fluidization bed

3 material requiring high micron, stable performance in high temperature.

4 High pressure backwash oil filter

Specifications:

1 standard material ; sus 316L,sus 304.

2.available size:≤1200x1000mm 1000mmx500mm,1200mmx600mm,1000mmx1000mm;

3.filtration ration: 1—300um

4.spec. size are available on request.

sintered multi—layer metal mesh is composed of laminated layers of wire cloth bonded special calendering and sintering in vacuum oven ,to create a new filter material with higher strength and rigidity. it is interlaced mesh forms an uniform and ideal filtration structure ,As a new filter material .it not only overcomes the disadvantages of ordinary metal mesh ,such as lower strength, poor rigidity, unstable hole shapes, but has excellent performance such as high precision and strength ,efficient flow restriction mechanical and resistance to abrasion, heat and cold by reasonably arranging its porosity permeability and strength .therefore ,its total performance has obviously advantages than sintered powder, ceramic, fiber cloth, other filter material.

our sintered mesh has been widely used in many industries such as aerospace,aviation,petroleum,chemical,metallurgy,machining,pharmaceutical,food,synthetic fiber ,film, environment al-protection industries in respect of filtration and purification ,gas-solid, liquid-solid and gas –liquid separation. cooling, gas distribution, fluidization bed ,gas samping collection, shock reducing ,sound attenuation, inflaming retarding.

Main application:

1 distribution and cooling material in high temperature

2 material used for gas distribution and fluidization bed

3 material requiring high micron, stable performance in high temperature.

4 High pressure backwash oil filter

Specifications:

1 standard material ; sus 316L,sus 304.

2.available size:≤1200x1000mm 1000mmx500mm,1200mmx600mm,1000mmx1000mm;

3.filtration ration: 1—300um

4.spec. size are available on request.

Related Products

-

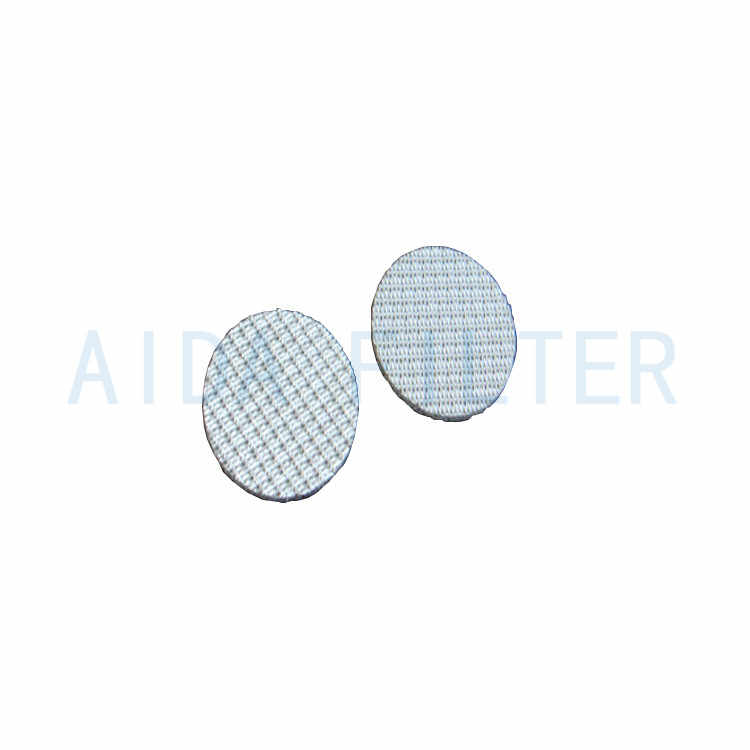

Manufacturer direct supply sintered stainless steel filter disc for explosion-pr

-

High quality sintered stainless steel filter disc for flame proof

-

High quality sintered stainless steel filter disc for chemical industry

-

High quality sintered stainless steel filter disc for power plant

Inquiry

Please kindly leave your detailed information. We will get in touch with you as soon as possible after receiving your message.